CNC Machining I & II and Engineering Design

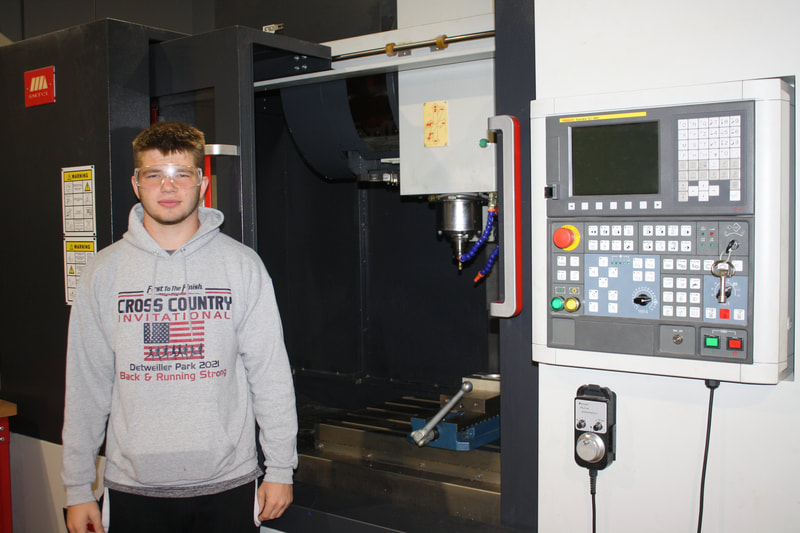

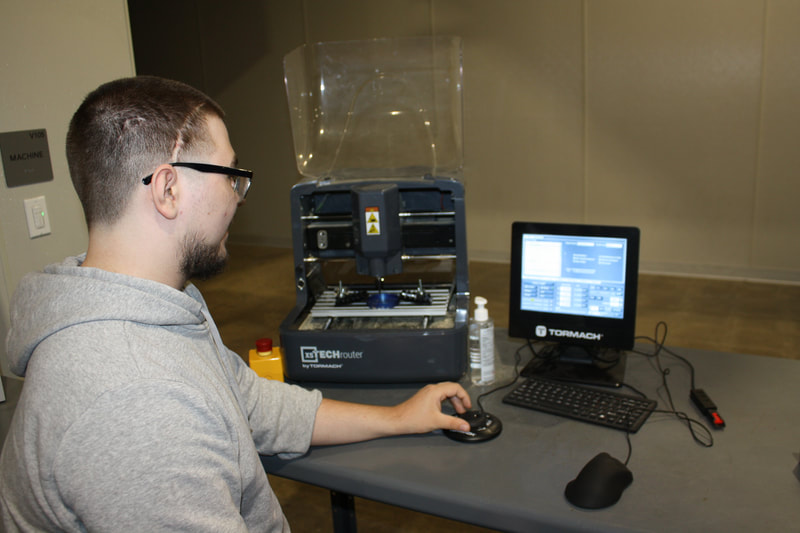

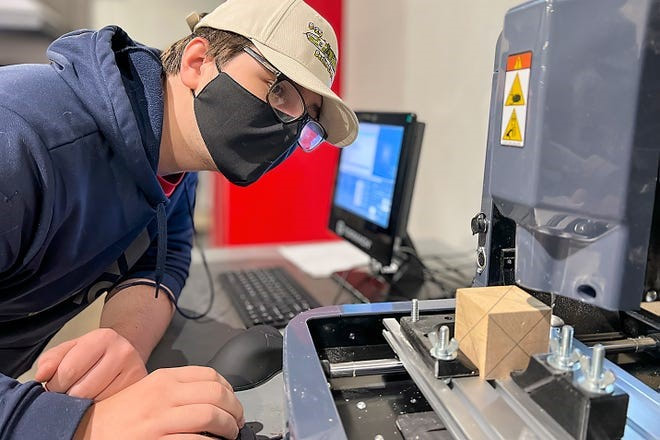

CNC I: This course provides an introduction to Computer Numerical Control (CNC) machining processes and the technology that supports them. Some of the processes covered are gauging, quality control, spot drilling, drilling, reaming, tapping, counter-boring, countersinking, defining and calculating speed and feed rates, screw thread identification, and drill sharpening. Students will perform these processes on manual equipment prior to observing them on CNC equipment. Occupational computer skills are also covered in this course. This course is dual credit with Carl Sandburg College.

CNC II: This course provides more in-dept skill development in various types of precision tool operation, especially using mills, lathes and surface grinders to perform machining tasks. Students will also explore the use of computer and numerical controlled machining in the lab. Students will receive college credit from CSC in addition to high school credit.

Engineering Design: This course students will learn the Engineering scope, content and professional practice are presented through practical applications. Students in engineering teams apply technology, science and mathematics concepts and skills to solve engineering design problems and create innovative designs. Students will research, develop, test and analyze engineering designs using criteria such as design effectiveness, public safety, human factors, and ethics. This course is the capstone experience for students who are interested in Technology, Innovation, Design, and Engineering.

CNC II: This course provides more in-dept skill development in various types of precision tool operation, especially using mills, lathes and surface grinders to perform machining tasks. Students will also explore the use of computer and numerical controlled machining in the lab. Students will receive college credit from CSC in addition to high school credit.

Engineering Design: This course students will learn the Engineering scope, content and professional practice are presented through practical applications. Students in engineering teams apply technology, science and mathematics concepts and skills to solve engineering design problems and create innovative designs. Students will research, develop, test and analyze engineering designs using criteria such as design effectiveness, public safety, human factors, and ethics. This course is the capstone experience for students who are interested in Technology, Innovation, Design, and Engineering.

Electrical Trades I & II

Electrical Trades I: Electronics is designed to foster awareness and understanding in electronic fields. AC and DC circuit concepts are taught through experimentation. Course work includes units on passive and active electrical devices as well as relationships between inductance, capacitance, and reactance. Series and parallel RC and RL circuit analysis will be presented. Students will use meters and oscilloscopes. Computers will be used to draw circuits and aid students in learning. Students will gain hands on experiences both in the classroom and in the lab. This course is open to students in grades 10,11 & 12.

Electrical Trades II: This class must be taken concurrently with Electrical Trades I. Areas of instruction in Electricity include: electrical theory, circuit design and operation, the national electrical code, blueprint reading, construction blueprint interpretation, and test equipment usage. Students plan and organize wiring tasks and gain practical experience by working mock-ups and trainers. Students troubleshoot circuits for faulty operation and make repairs. Specific studies include AC and DC theory, series and parallel circuits, motor controls and generator theory, lighting and appliance wiring, low voltage wiring and testing repair. This course is offered as dual credit course with Carl Sandburg College. Students will be required to complete CSC enrollment requirements to enroll.

Electrical Trades Brochure trades_2324.pdf

Electrical Trades II: This class must be taken concurrently with Electrical Trades I. Areas of instruction in Electricity include: electrical theory, circuit design and operation, the national electrical code, blueprint reading, construction blueprint interpretation, and test equipment usage. Students plan and organize wiring tasks and gain practical experience by working mock-ups and trainers. Students troubleshoot circuits for faulty operation and make repairs. Specific studies include AC and DC theory, series and parallel circuits, motor controls and generator theory, lighting and appliance wiring, low voltage wiring and testing repair. This course is offered as dual credit course with Carl Sandburg College. Students will be required to complete CSC enrollment requirements to enroll.

Electrical Trades Brochure trades_2324.pdf

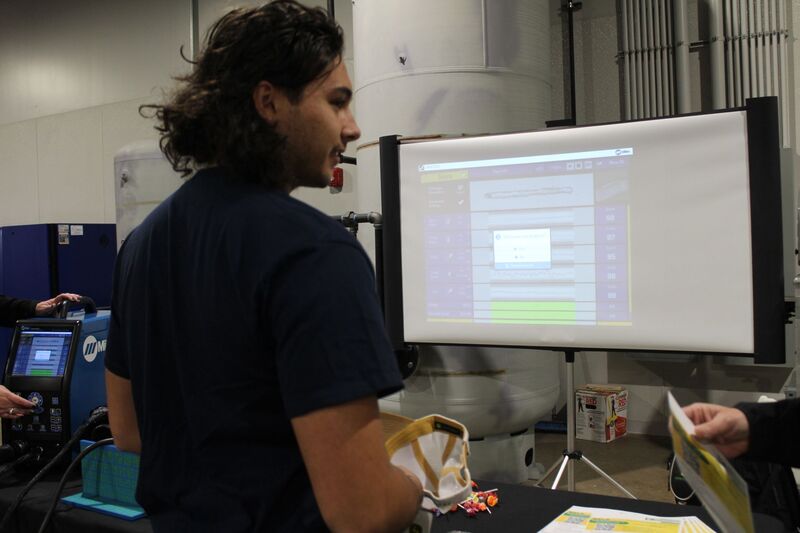

Welding

This course is designed for students who are planning a career in either production or job shop industrial welding. The main objective is to acquire the skills and the knowledge necessary to enter industry as a beginning welder. Much time will be spent in the welding lab. The course will include stick arc welding, MIG welding, TIG welding, plasma cutting, cutting torches, brazing, braze welding, submerged arc, blue prints and shop safety. This course is held at the Center for Manufacturing Excellence/CSC. Students will receive college credit in addition to high school credit.

Welding Brochure

| welding_2324.pdf | |

| File Size: | 895 kb |

| File Type: | |